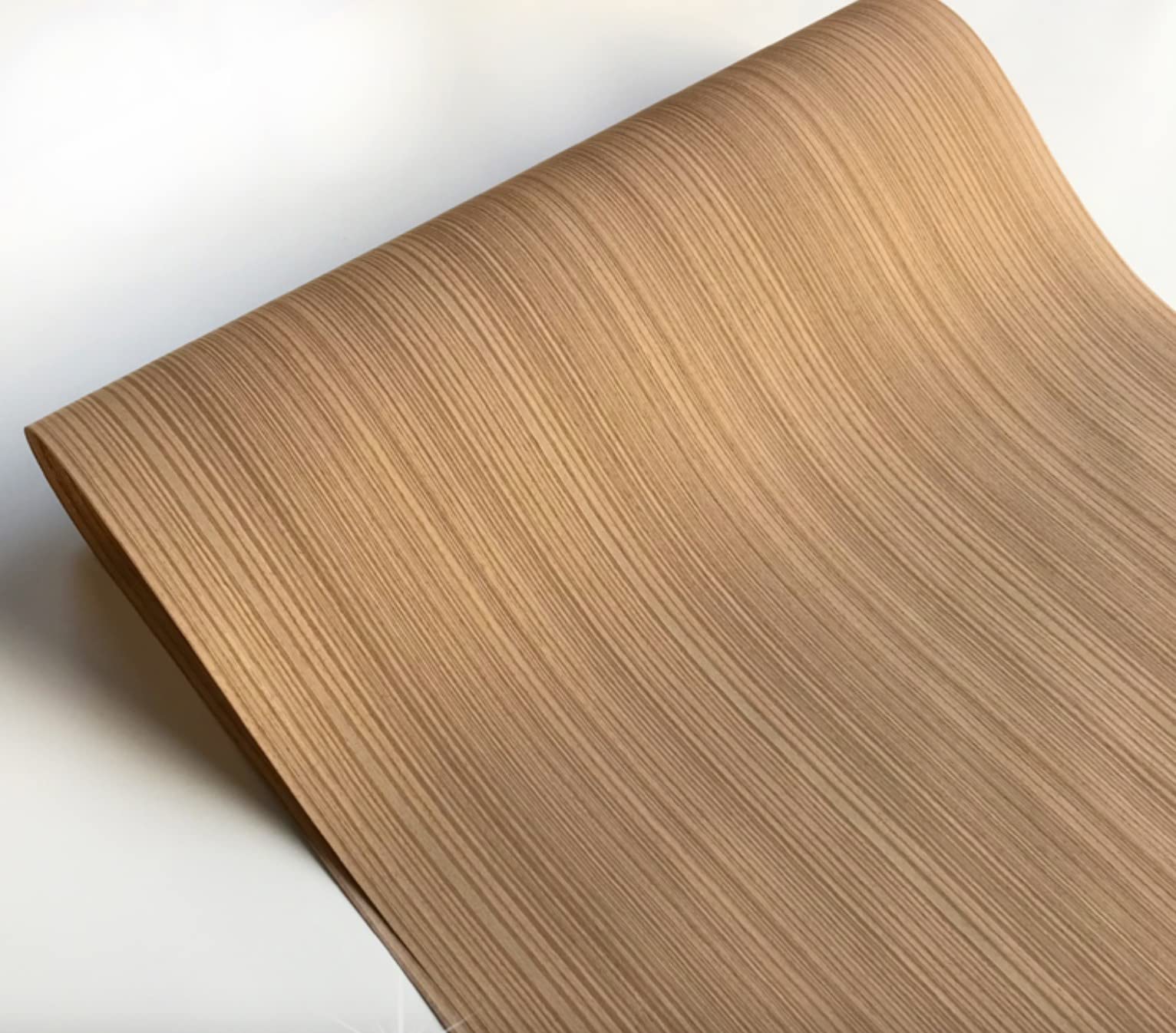

Engineered veneer (EV) – also known as reconstituted veneer (recon) or recomposed veneer (RV) – is a remanufactured product.

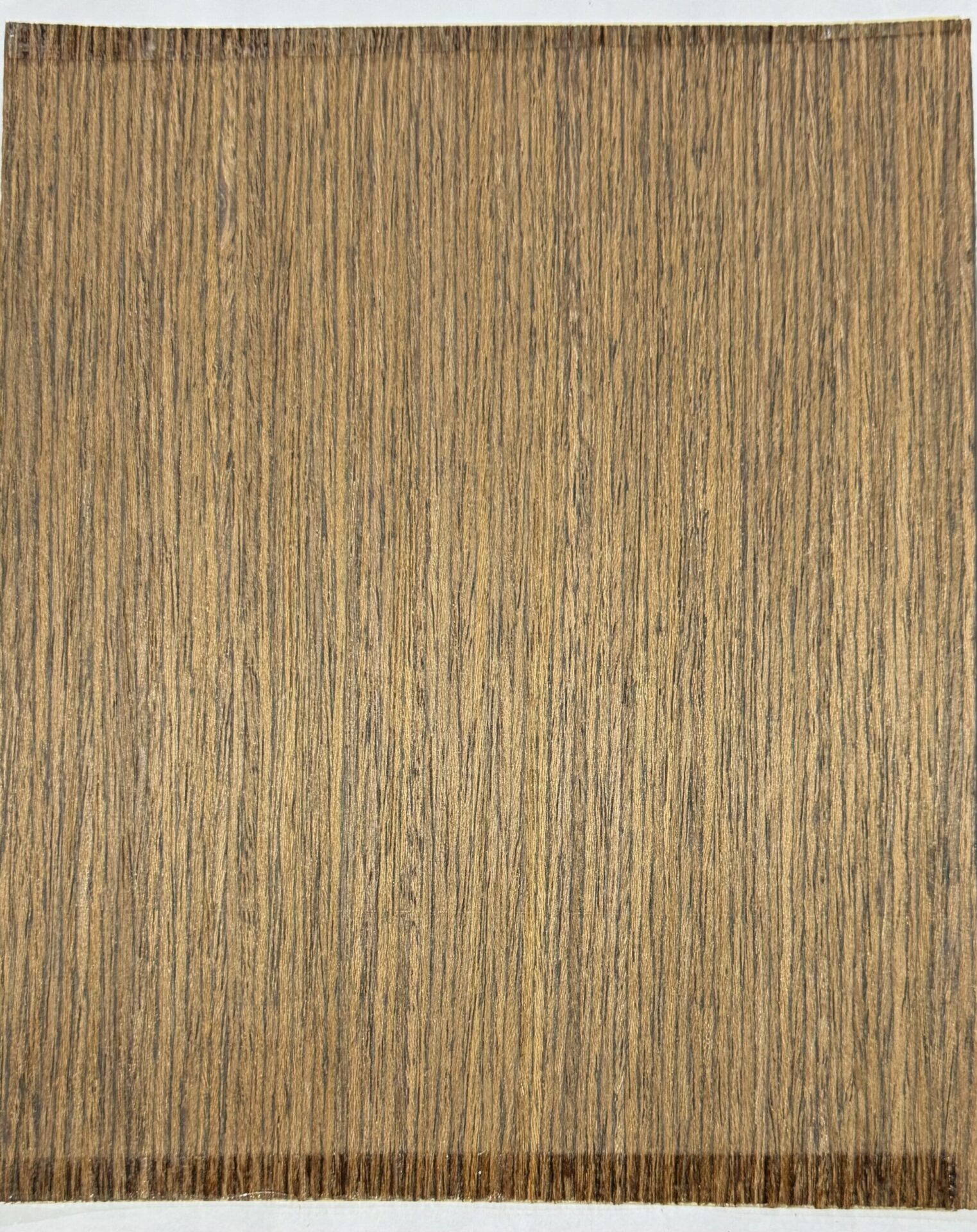

Like natural veneer, engineered veneer is real-wood and born from a natural core. The difference is that the veneer is engineered though templates and pre-developed dye moulds. This means that typically engineered veneers will be more consistent in terms of appearance and color – and will generally be free of surface knots and other natural characteristics found in each species, while still maintaining the natural wood grain from the core species used.Engineered veneer sheets are derived from renewable tree types.

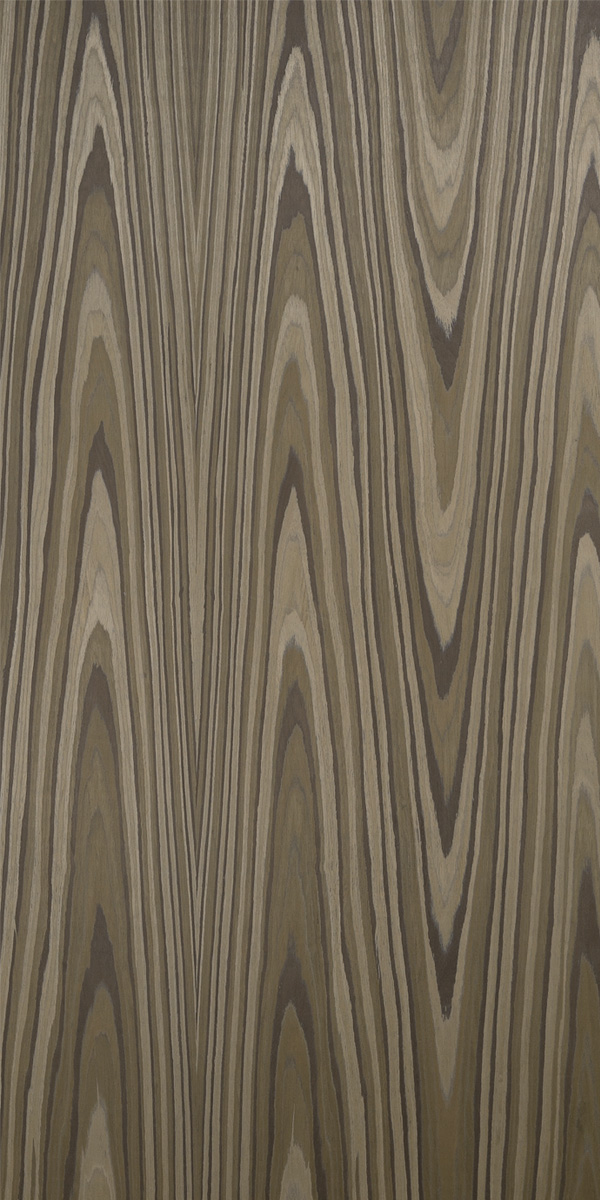

Artificial veneer sheets are intricately designed to mimic the distinctive grain patterns found in natural veneer. Employing a patented process, these sheets replicate similar designs on a larger scale. Ideal for decorative purposes, options like designer veneer and metallic veneer offer a perfect choice for enhancing surfaces, including furniture, walls, and flooring.

Artificial veneer sheets are intricately designed to mimic the distinctive grain patterns found in natural veneer, offering an aesthetically appealing alternative with added durability and versatility. Utilizing a patented manufacturing process, these sheets accurately replicate the organic look of natural wood on a larger, more consistent scale. This process allows for greater control over color, texture, and pattern, ensuring that each sheet has a uniform appearance, making it ideal for projects requiring consistency across multiple panels or surfaces.

These artificial veneer sheets are particularly suited for decorative purposes, as they can be customized to fit a wide range of design styles and color schemes. Options like designer veneer, which may incorporate unique colors and finishes, and metallic veneer, which can add a sleek, modern touch, are perfect choices for enhancing various surfaces. They are frequently used on furniture, walls, and flooring, where they provide a high-end look without the need for regular maintenance associated with natural wood.

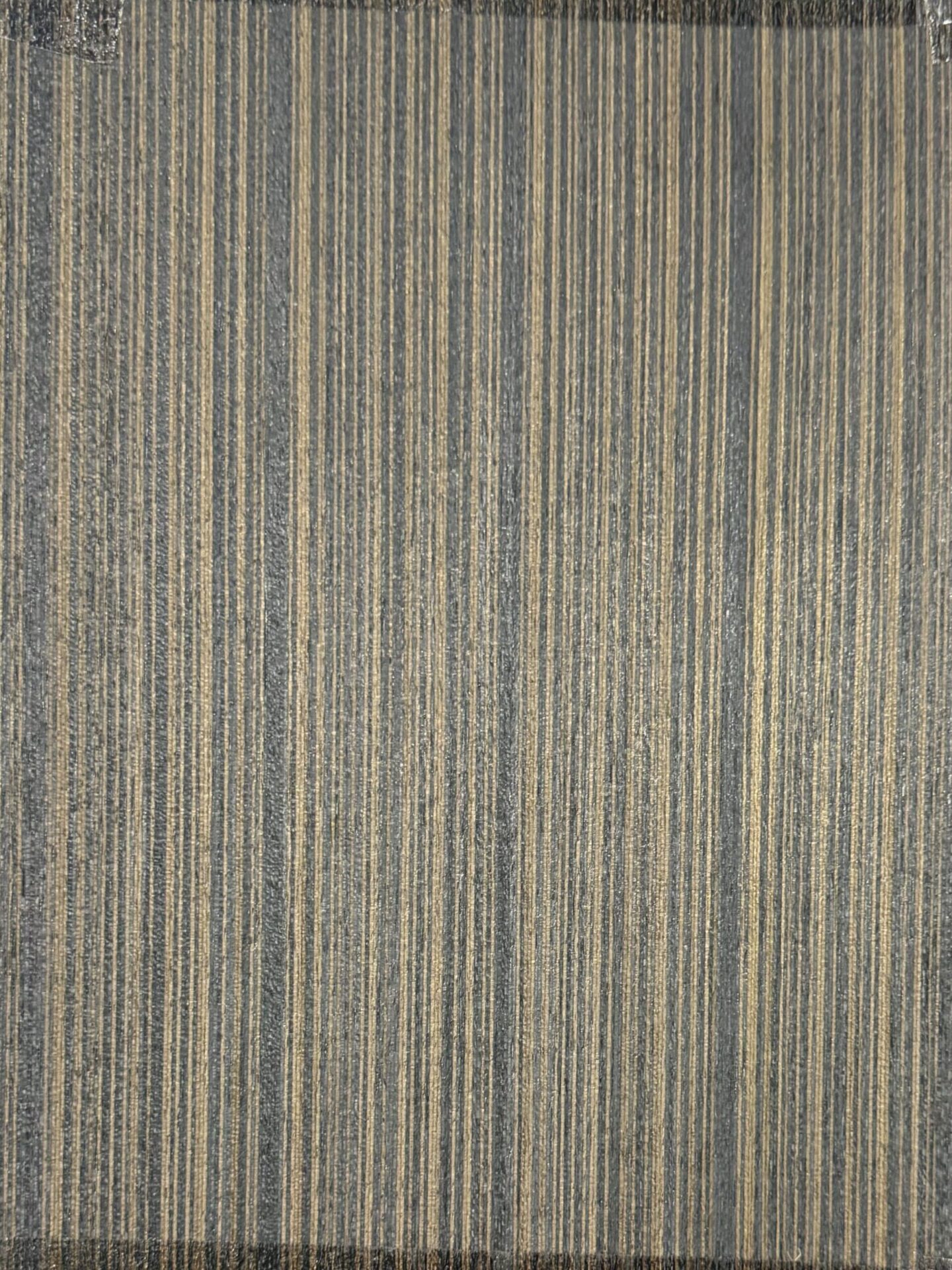

In addition to offering aesthetic flexibility, artificial veneer sheets boast improved durability compared to natural veneer. Many are resistant to moisture, UV rays, and scratches, making them well-suited for both residential and commercial applications. This makes them a practical option for high-traffic areas such as kitchens, offices, and retail spaces, where surfaces need to withstand daily wear and tear while maintaining their appearance over time.

The lightweight nature of artificial veneer also makes it easier to handle and install, allowing for quicker and more cost-effective project completion. Because it is typically made from engineered materials, it is less likely to warp or crack under changing environmental conditions, offering long-term stability that is ideal for a variety of interior applications. Furthermore, the production of artificial veneer often involves sustainable practices, as it minimizes the need for harvesting natural wood and reduces the overall environmental impact. Many artificial veneer sheets are also made from recycled materials, further enhancing their eco-friendly appeal.

For centuries, solid wood has been the cornerstone of exquisite furniture and captivating interiors. But what if there was a way to achieve that same timeless elegance with a material that boasts enhanced functionality with a lower cost. Enter engineered veneer, a revolutionary product rapidly transforming the design landscape.

Engineered veneer goes beyond the limitations of traditional wood. It’s crafted by reconstituting genuine wood elements – thin slices or strands – and bonding them to a stable core substrate. This innovative process unlocks a multitude of benefits: